The winter months allow Freeboard Technology staff to inspect, service, and upgrade buoys, ensuring each deployment is as effective and reliable as possible in the year ahead.

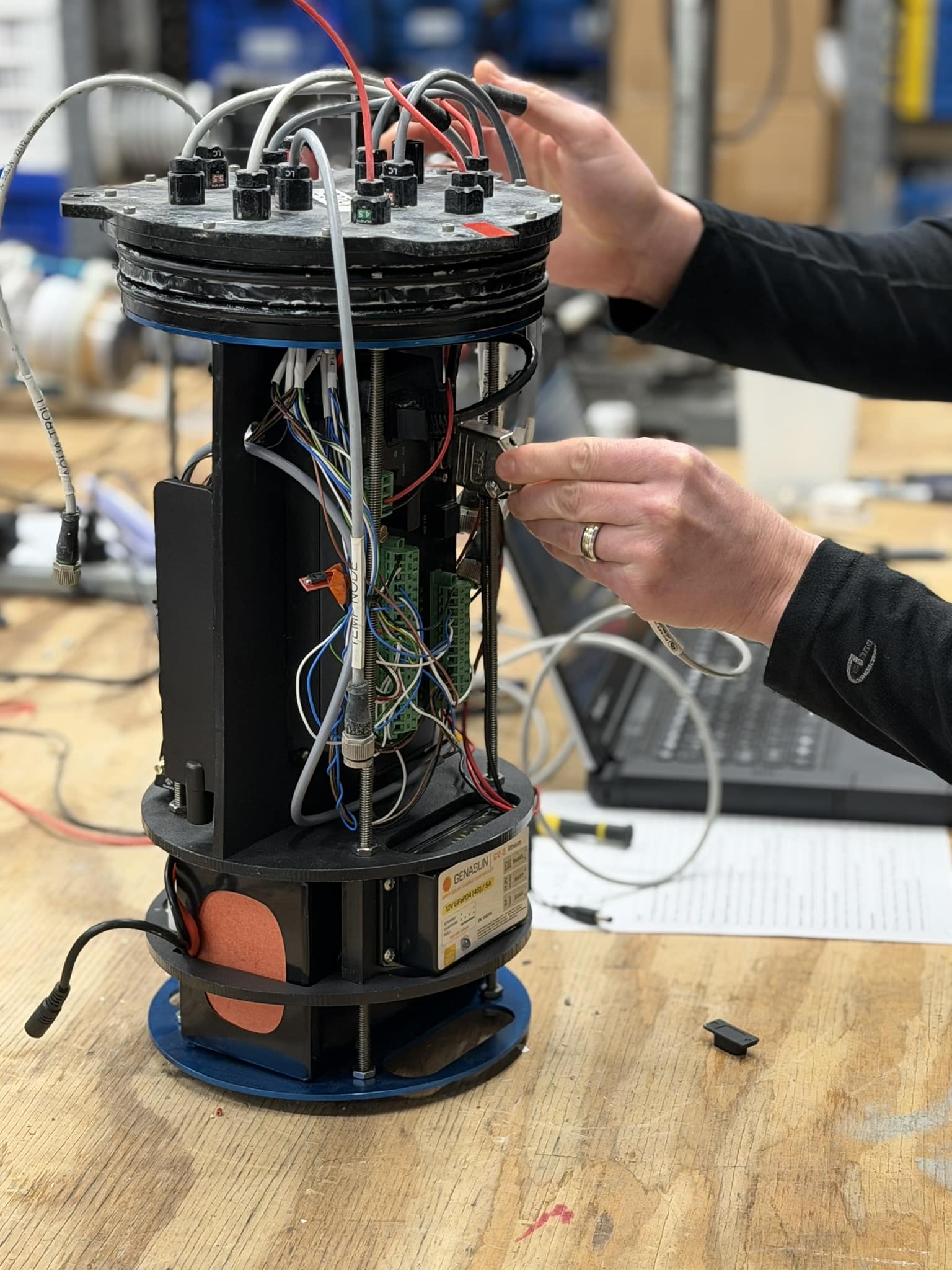

The first step of the offseason isn’t glamorous—but it’s essential: cleaning. Thorough cleaning helps ensure accurate sensor measurements while also removing significant excess weight. Clean solar panels are equally critical; when panels are obscured by buildup, their ability to capture sunlight is reduced, which can impact battery performance and data collection.

Hard water deposits, algae, biofouling, bird droppings, and tangled fishing line are among the usual culprits. Each buoy receives a full power wash and is then hand-scrubbed to maintain the condition of all mechanical components. Solar panels, often clouded by mineral buildup or debris, are treated with a specialized cleaning solution to maximize power generation throughout the deployment season—supporting the high-frequency, data-dense sampling our users rely on.

Once cleaned, the focus shifts to accuracy and reliability. Sensors are individually inspected and cleaned, and those requiring calibration are serviced accordingly. This may include sending specialized water-quality sensors to OEMs or certified technicians for refresh or repair. Consumable components are checked for wear and replaced as needed. Routine sensor maintenance not only helps prevent in-season failures but also extends the equipment’s overall lifespan.

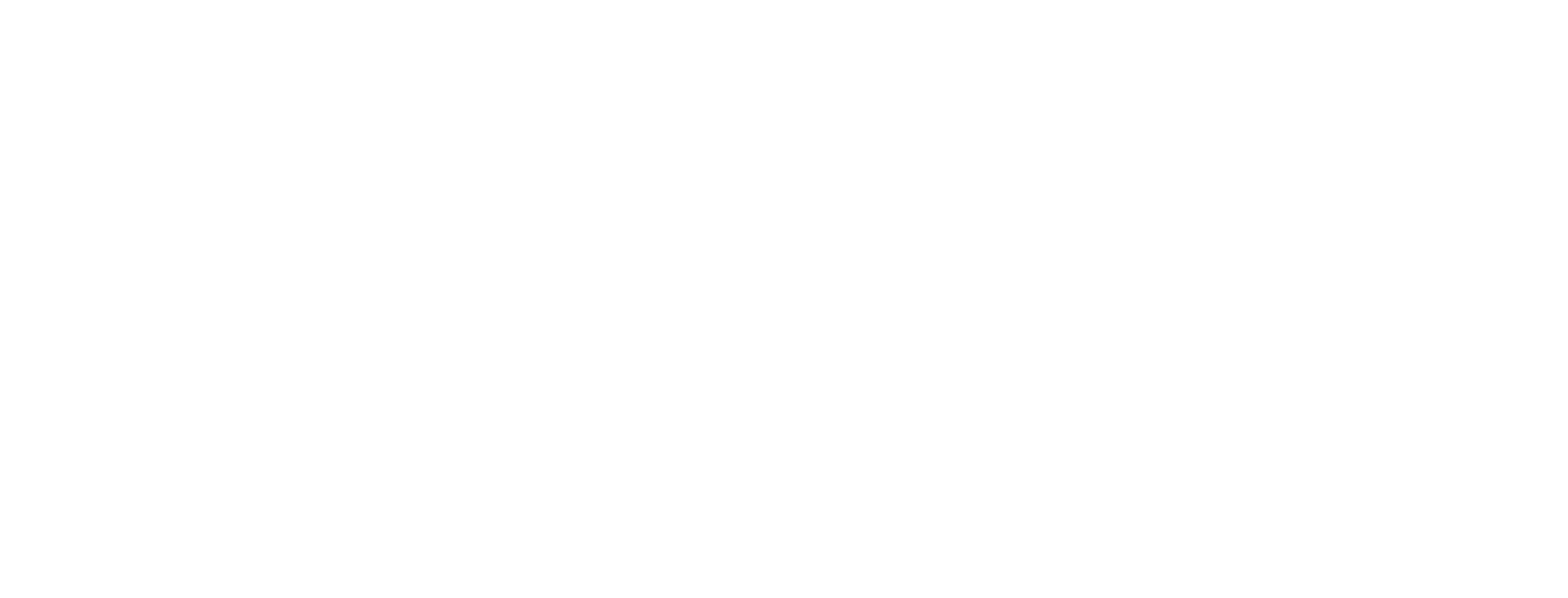

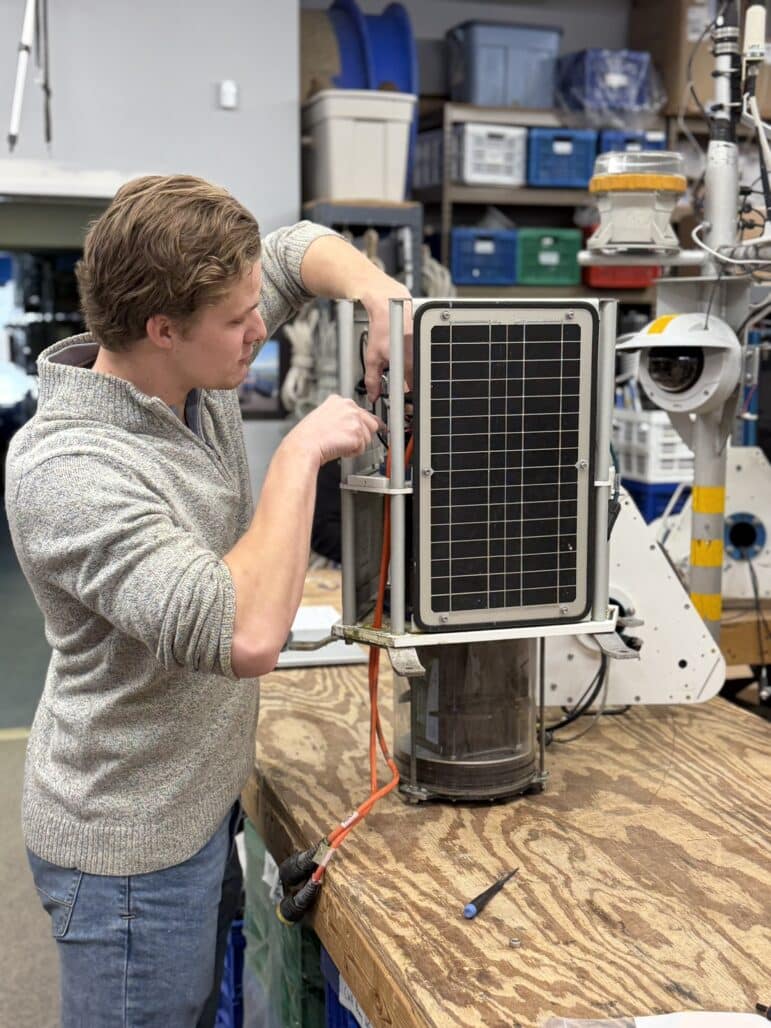

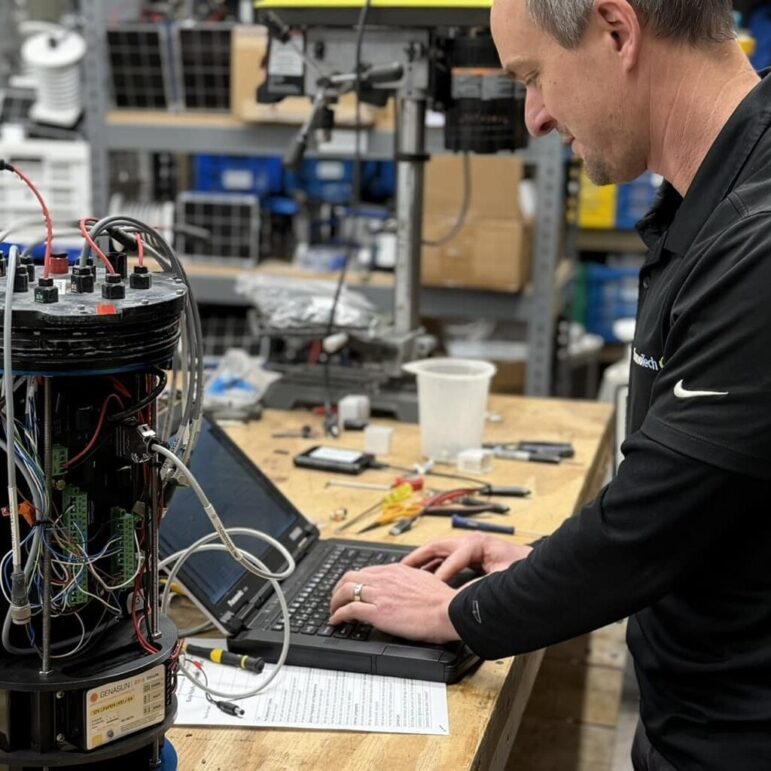

Next, the buoy’s electronic components—the “smart parts”—are separated from the floats and frames and evaluated using a multi-point inspection checklist. Waterproof seals are examined and maintained, connectors are tested for proper performance, and every electrical connection is verified to be secure.

The offseason also provides an ideal window for system upgrades. These updates may include integrating new sensors, improving maintainability, or converting buoys to newer configurations. Recently, many systems have been upgraded to Freeboard’s Orca buoy, which offers a robust, streamlined enclosure for solar panels, electronics, and batteries. Freeboard also supports collaborative efforts between organizations looking to expand an existing buoy’s capabilities rather than build a new system from scratch.

Finally, the buoys are fully reassembled and undergo comprehensive final testing. This includes validating sensor performance under simulated conditions, exposing enclosures to submersion and water spray, and confirming all mechanical connections are secure. Once complete, the buoys are ready for deployment.

This offseason maintenance process results in higher-quality data, reduced downtime, and a better overall customer experience. If you have questions about buoy maintenance or are interested in working with Freeboard Technology on a buoy or sensor project, please reach out through our Contact page.